Hose inspection & testing

hyDROSTATIC TESTING

Simply put, Hydrostatic Testing involves filling a hose assembly with water and taking it to a pre-specified test pressure, generally 1.5 times the maximum working pressure and holding it for a set period of time. Whilst under pressure the hose is monitored and inspected to ensure that the pressure is held and its integrity is maintained.

Why Test Flexible Hose Assemblies?

Why Test Flexible Hose Assemblies?

Leaking hose assemblies are a risk to personal health and safety and there are many environmental issues associated with unwanted emissions. They can also be very costly in the form of lost production due to unforeseen outages.

Buckley Industrial’s philosophy of preventative testing virtually eliminates any unpleasant surprises and allows Customers to carefully manage planned maintenance thereby maximising the up time of their production process.

Buckley Industrial specialises in the testing of flexible hose assemblies and we refer to this throughout the inspection and testing element of this website. Our procedures are, however, equally applicable to other types of pressure components such as expansion joints, couplings etc.

Inspection and Testing Overview

Buckley Industrial is a specialist test house employing state of the art precision test equipment operated by experienced personnel. The hose testing techniques employed are:

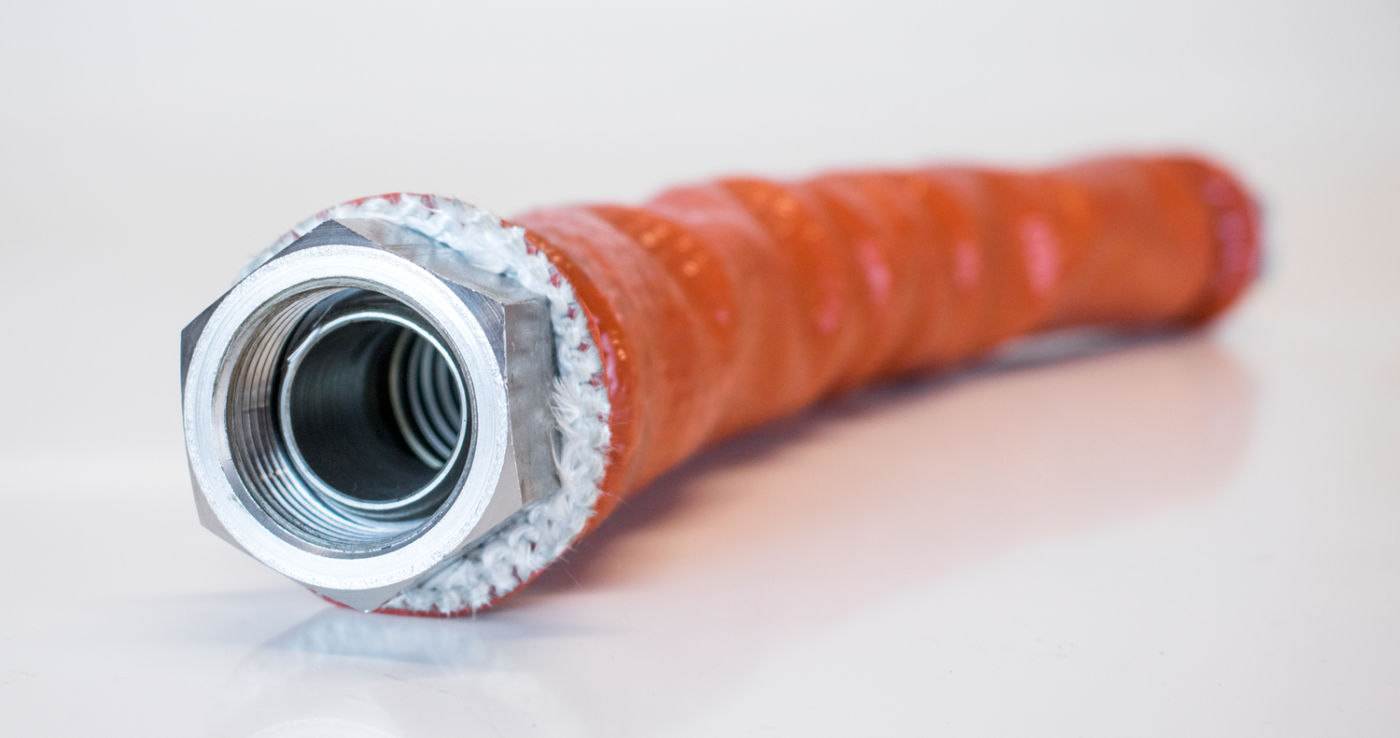

- Visual Inspection – examining the outside of a hose looking for any defects which could cause it to leak during service.

- Hydrostatic Testing – pressurising water within a hose to ensure it can hold pressure without leaking.

- Nitrogen Testing – pressurising a hose with Nitrogen whilst underwater to ensure it can hold pressure without leaking.

- Internal Inspection – examining the inside of a hose looking for any defects which could cause it to fail during service.

- Electrical Continuity Test – testing for an electrical bond between the end fittings of a hose assembly to avoid static build-up within the length of the hose.

- Helium Testing – used to find leaks through the product. The helium is used as a tracer gas and its concentration is measured.

Please click on any of the headings for a more detailed description.